Exhibitors' information

Mitsubishi Heavy Industries, Ltd.

【MHI's Continuous Challenge to realize Fusion Energy】

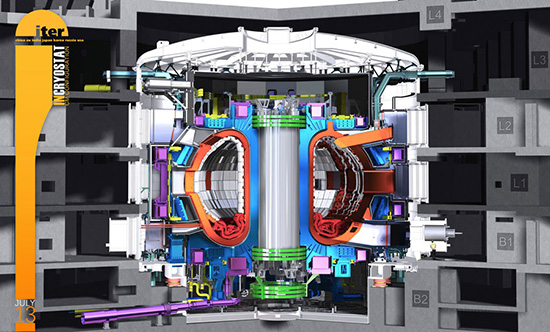

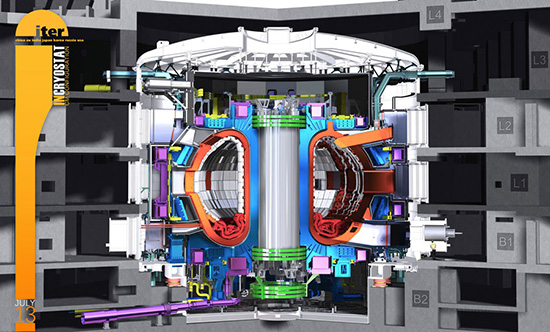

MHI has been working on the ITER Project, which is an international project for fusion experimental reactors, and it is a challenge to realize fusion energy for the future.

MHI is involved in many of the components and systems procured by Japan and contributes to the successful completion of the ITER Project.

(This PJ is being promoted together with the National Institutes for Quantum Science and Technology.)

MHI has participated in the Fusion DEMO program and will continue to make efforts for the realization of Fusion Energy, the details are described here.

Click here for the 「MHI's Fusion Energy」

【©ITER Organization, http://www.iter.org/】

【MHI's efforts and contribution to ITER】

MHI is in charge of manufacturing 5 of 19 toroidal magnetic field coils (TF coils), which are the major components in the ITER tokamak machine. In January 2020, we completed the very first TF coil in the world and delivered it in February 2020. Up to now, we completed 4 units and shipped them to France.

Though the size of a TF coil is more than 10 m, it must be manufactured with a dimensional accuracy of a few mm, in order to confine plasmas stably. The TF coil structure is made from thick forgings to withstand a huge electromagnetic force during operation.

【MHI's manufacturing technologies】

[Project Story]

MHI has been working on the ITER Project, which is an international project for fusion experimental reactors, and it is a challenge to realize fusion energy for the future.

MHI is involved in many of the components and systems procured by Japan and contributes to the successful completion of the ITER Project.

(This PJ is being promoted together with the National Institutes for Quantum Science and Technology.)

MHI has participated in the Fusion DEMO program and will continue to make efforts for the realization of Fusion Energy, the details are described here.

Click here for the 「MHI's Fusion Energy」

【©ITER Organization, http://www.iter.org/】

【MHI's efforts and contribution to ITER】

MHI is in charge of manufacturing 5 of 19 toroidal magnetic field coils (TF coils), which are the major components in the ITER tokamak machine. In January 2020, we completed the very first TF coil in the world and delivered it in February 2020. Up to now, we completed 4 units and shipped them to France.

Though the size of a TF coil is more than 10 m, it must be manufactured with a dimensional accuracy of a few mm, in order to confine plasmas stably. The TF coil structure is made from thick forgings to withstand a huge electromagnetic force during operation.

【MHI's manufacturing technologies】

The TF coil is a huge structure with a height of 16.5 meters, a width of 9 meters for a total weight of more than 300 tons, and it is manufactured with an accuracy of 1/10,000 or less. We have established advanced welding technologies in order to avoid excess welding deformation.

As for manufacture of the Divertor, we established bonding technology between tungsten and copper alloy, welding technology for dissimilar materials (copper alloy and stainless steel) and non-destructive inspection technology through performing preliminary tests and manufacturing protypes.

Click here for the manufacturing technology materials of TF coil and Divertor

As for manufacture of the Divertor, we established bonding technology between tungsten and copper alloy, welding technology for dissimilar materials (copper alloy and stainless steel) and non-destructive inspection technology through performing preliminary tests and manufacturing protypes.

Click here for the manufacturing technology materials of TF coil and Divertor

[Project Story]

We would like to introduce the opinions of the young engineers in charge of manufacturing the ITER TF coils about efforts for implementing the advanced manufacturing technologies to achieve the high precise dimensions required for the ITER TF coil.

Click here for the「Project Story」.

Click here for the「Project Story」.

-

Department

Nuclear Systems Engineering Dept.Nuclear Energy Systems

-

Address

100-8332

Marunouchi-Nijubashi Bldg.,2-3 Marunouchi 3-Cyome, Chiyoda-ku, Tokyo -

Web site, SNS

https://www.mhi.com/ https://www.mhi.com/products/energy/nuclear_power_generation_list